Understanding the FM25V02A-GTR and Common Issues

The FM25V02A-GTR is a 2Mb (256KB) ferroelectric RAM (FRAM) device designed for low Power consumption and high durability. It is often used in a variety of applications where reliability and performance are crucial, such as data logging, automotive, medical, and industrial control systems. Despite its robustness, like any electronic component, the FM25V02A-GTR is not immune to malfunctions, and understanding the potential problems can help mitigate issues early on.

1. Power Supply Issues

One of the most common issues that users face with the FM25V02A-GTR is power supply instability. If the voltage provided to the device is too low or fluctuates too much, it can cause erratic behavior or failure to write or read data. This issue can arise from poor power regulation in the circuit or faulty connections.

Solution:

To resolve power supply issues, first, ensure that the voltage meets the required levels for the FM25V02A-GTR. The device typically operates at 3.3V, so double-check that your power supply provides stable voltage within the specified range (usually ±5% tolerance). Use a dedicated voltage regulator to minimize power fluctuations. You should also inspect the power rails for noise, as spikes or drops can cause the device to behave unpredictably.

2. Data Corruption and Memory Integrity Problems

Data corruption in the FM25V02A-GTR can occur due to a variety of factors, including electrical noise, sudden power loss, or even improper handling of read/write operations. FRAM devices, while more resilient than traditional flash memory, can still experience issues if the memory interface or the associated circuitry is not correctly designed or implemented.

Solution:

When troubleshooting data corruption, start by checking the I2C or SPI interface (depending on your setup) for proper signal integrity. Use an oscilloscope to monitor the waveform of the Communication signals and verify they meet the expected logic levels. Make sure that your read and write cycles are appropriately timed and that no conflicting operations are happening simultaneously.

Additionally, to prevent data corruption from power loss, consider adding a capacitor or a power-fail detection circuit to your design. This will help preserve the data integrity during power outages or voltage drops. FRAM's low power consumption can make this approach particularly effective, as it can store data even during short-term power interruptions.

3. Communication Failures

Another issue that users often report is communication failures between the FM25V02A-GTR and the microcontroller or other components in the system. Communication errors can lead to the device failing to respond to read or write commands, preventing proper data exchange.

Solution:

First, ensure that your clock and data lines are properly connected and that the I2C/SPI protocol matches the configuration expected by the FM25V02A-GTR. Common issues in communication often stem from incorrect pull-up resistors or improper baud rates. In the case of I2C communication, make sure the SDA and SCL lines are correctly terminated and not too long, as signal degradation can occur over longer distances.

For SPI, verify that the clock polarity and phase settings are correct according to the device’s specifications. Also, check the chip-select (CS) line, as improper handling of this pin can prevent proper communication.

4. Temperature Sensitivity

Extreme temperatures can affect the performance of the FM25V02A-GTR. While it operates within a specified temperature range, excessive heat or cold can cause the memory to malfunction or exhibit erratic behavior. Overheating is often a concern in industrial applications where devices are exposed to harsh conditions.

Solution:

To solve temperature-related problems, it is essential to place the FM25V02A-GTR in an environment where temperature extremes are avoided. If your application involves exposure to high temperatures, consider using heat sinks or improving ventilation in the housing of the device. For low-temperature conditions, use thermal insulation or heaters to maintain the device within its operational temperature range.

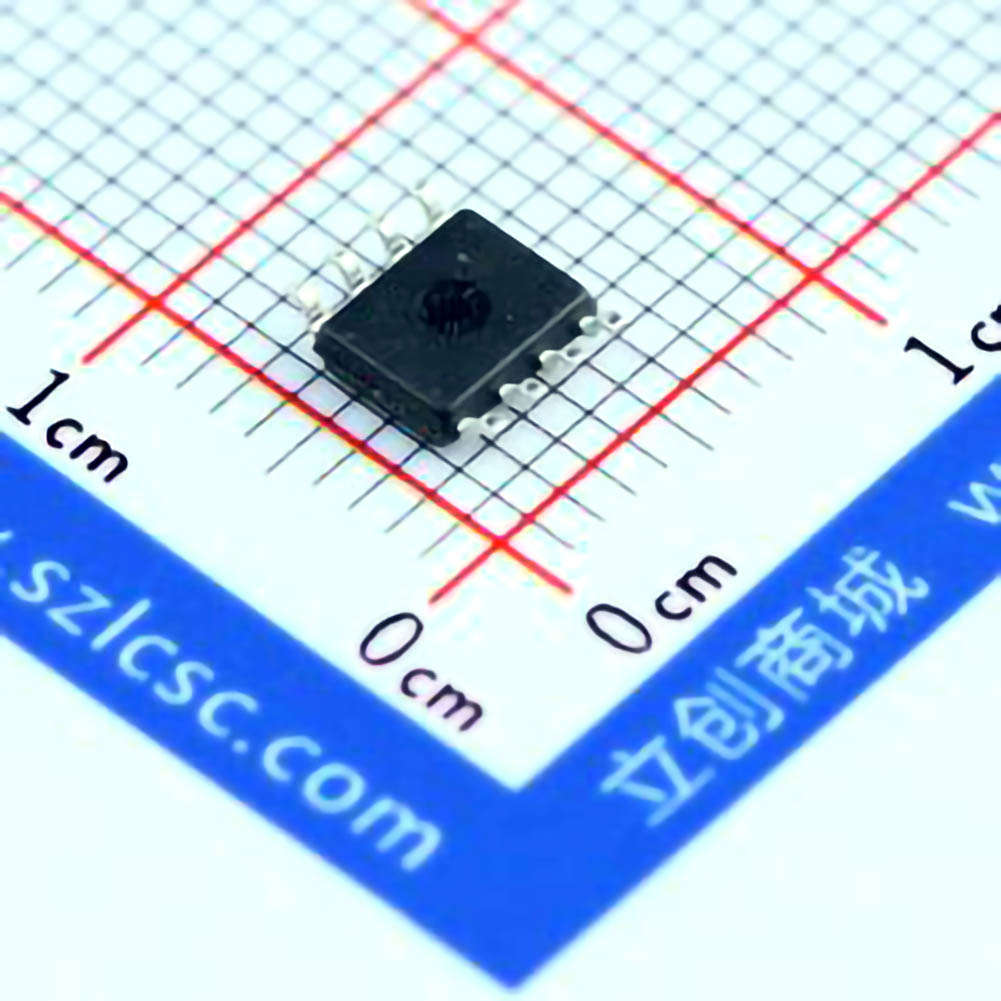

5. Physical Damage or Defects

Physical damage to the FM25V02A-GTR can also lead to malfunctioning. This can include damaged pins, poor solder joints, or static discharge. It’s important to inspect the device thoroughly to ensure that there is no visible damage.

Solution:

Ensure that proper electrostatic discharge (ESD) protection is in place when handling the FM25V02A-GTR. Avoid touching the pins directly and use anti-static mats and wrist straps. Inspect the soldering connections and look for any signs of loose or cold solder joints that may cause intermittent or unreliable connections. If physical damage is detected, consider replacing the device.

Advanced Troubleshooting Tips and Long-Term Solutions

While addressing the basic issues listed above is often sufficient to resolve common FM25V02A-GTR problems, more advanced troubleshooting methods and long-term solutions may be necessary for sustained reliability. These steps can help extend the device's lifespan, improve performance, and avoid future complications.

1. Utilizing a Robust Testing Setup

One of the best ways to ensure that the FM25V02A-GTR operates correctly is by integrating a robust testing setup into your development and production processes. This can help identify issues early and prevent potential failures before they affect the end-user.

Solution:

To build a comprehensive testing environment, incorporate diagnostic tools such as oscilloscopes, logic analyzers, and signal generators. These tools can help detect minute issues with signal integrity, communication errors, and data corruption. Implement a test routine that checks all aspects of the device’s functionality, from power-up behavior to read/write operations. It’s also crucial to simulate different environmental conditions, such as power failures and temperature extremes, to ensure the system behaves as expected.

2. Optimizing Software Control and Algorithms

Sometimes, the issue with the FM25V02A-GTR isn’t hardware-related but rather due to inefficient software control or improper timing of operations. Improper initialization or failure to handle error conditions in the software can result in failed writes or reads.

Solution:

Review the software routines that interface with the FM25V02A-GTR. Ensure that proper error handling mechanisms are in place to recover from unexpected conditions, such as communication timeouts or corrupted data. Implementing checksum or CRC algorithms in your software can provide additional data integrity checks, ensuring that any anomalies are detected and handled properly.

Also, fine-tune the timing of your read/write operations. The FM25V02A-GTR’s response times are fast, but poorly timed operations may cause data loss or communication errors. Make sure that the timing requirements are followed closely and that the device is given enough time to complete each operation before initiating the next.

3. Using Alternative Memory Technologies as Backups

In certain applications, critical data loss could have severe consequences. While the FM25V02A-GTR is highly reliable, it’s worth considering alternative memory technologies as a backup to further enhance data safety.

Solution:

One way to protect against data loss is to implement a dual-memory system, where critical data is mirrored between the FM25V02A-GTR and a secondary memory device, such as EEPROM or flash memory. This provides redundancy, ensuring that if one memory type fails, the other can continue to function. Additionally, you can use real-time data logging to back up important data continuously, ensuring that it is always stored in multiple locations for maximum reliability.

4. Regular Maintenance and System Monitoring

Preventative maintenance is often overlooked, but it can be key in extending the lifespan and performance of the FM25V02A-GTR. Over time, environmental factors such as dust, humidity, and temperature fluctuations can lead to gradual degradation of the device’s performance.

Solution:

Implement a regular system monitoring schedule that checks for early signs of failure, such as slow read/write speeds, increased error rates, or rising temperatures. Ensure that the device is housed in a clean, controlled environment and that any external factors that could affect its performance are minimized.

Conclusion

Troubleshooting and maintaining the FM25V02A-GTR memory device may seem daunting, but with the right knowledge and strategies, common issues can be resolved effectively. By addressing power supply issues, ensuring reliable communication, safeguarding data integrity, and taking a proactive approach to system monitoring, you can maximize the device’s performance and longevity. By combining these troubleshooting tips with long-term solutions, you’ll ensure that your FM25V02A-GTR continues to deliver reliable performance in your systems for years to come.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.