In the world of modern electronics, efficient Power conversion is essential for optimizing performance and reducing energy consumption. The MP2451DT-LF-Z , a high-performance DC-DC buck converter, stands out due to its versatility and compact design. This article explores the application and Thermal Management strategies associated with the MP2451DT-LF-Z, highlighting its role in DC-DC power conversion and the critical importance of effective thermal design.

The MP2451DT-LF-Z in DC-DC Converters : A Game-Changer in Power Efficiency

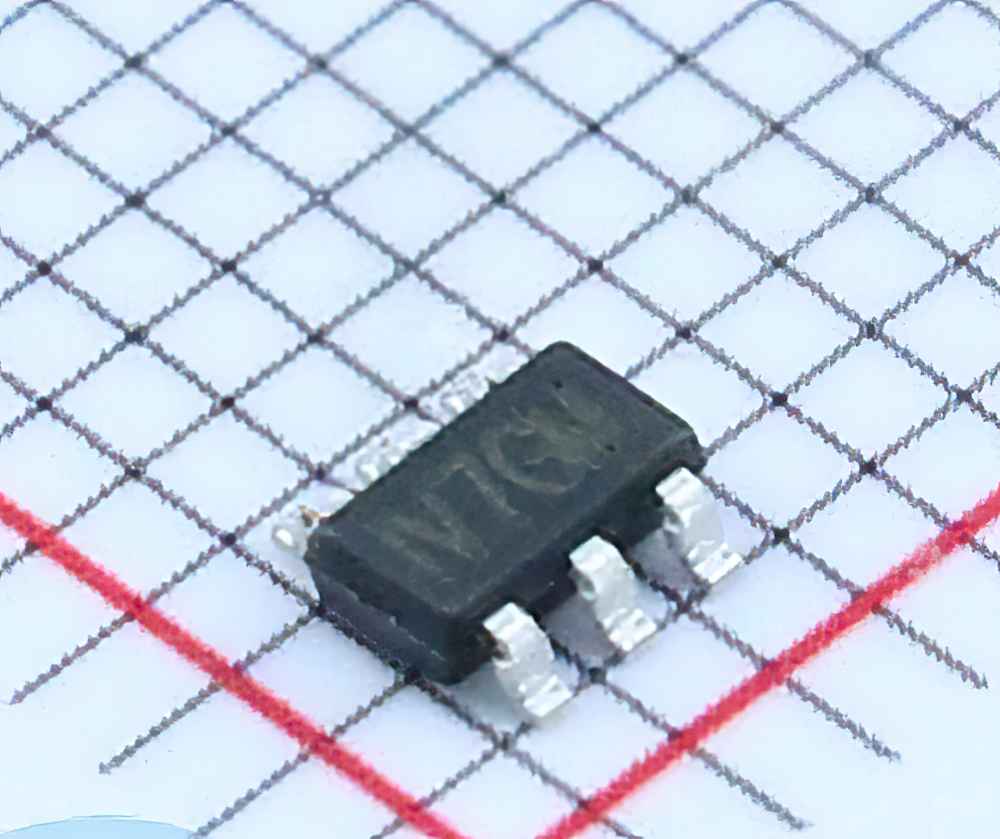

The MP2451DT-LF-Z is a high-efficiency, integrated buck converter that has gained significant popularity in applications requiring efficient power regulation. It provides a compact solution to power conversion challenges, delivering stable output voltages from a variety of input sources, ranging from 4.5V to 60V. As a part of Monolithic Power Systems' (MPS) portfolio, the MP2451DT-LF-Z has made waves in industries such as automotive, Telecom munications, industrial automation, and consumer electronics.

1. Overview of the MP2451DT-LF-Z

At its core, the MP2451DT-LF-Z is a synchronous buck regulator designed to efficiently step down voltage for powering sensitive electronics. It provides a high level of performance with minimal external components, offering a current output capability of up to 5A. This makes it ideal for applications where space and energy efficiency are at a premium, such as battery-powered devices and embedded systems.

The device's features include high efficiency, low standby current, and a wide input voltage range, making it an excellent choice for a broad range of industrial and commercial applications. The MP2451DT-LF-Z also incorporates an internal compensation network, reducing the need for external components and simplifying circuit design.

One of the key selling points of this buck converter is its versatility. With adjustable output voltages that can be programmed through external resistors, the MP2451DT-LF-Z can be tailored to meet the specific needs of the application. This adaptability makes it suitable for everything from low-power devices to high-power industrial equipment.

2. Role of DC-DC Converters in Modern Power Systems

DC-DC converters are crucial components in any system that involves power regulation. These converters are used to step down (buck) or step up (boost) the input voltage to a desired output level. They play a critical role in ensuring that electronic devices receive the right amount of power without overloading or wasting energy.

The MP2451DT-LF-Z is specifically designed to serve as a buck converter, which is often the preferred topology for applications where a higher input voltage needs to be stepped down to a stable and lower output voltage. This could include scenarios where battery voltage is being regulated or where an unregulated supply needs to be adjusted to power sensitive components.

The buck converter design is highly efficient because it uses a switch-mode approach rather than linear regulation. This allows for less energy loss in the form of heat, contributing to overall power savings and improving the longevity of devices by reducing thermal stress. Efficiency rates of up to 96% can be achieved with the MP2451DT-LF-Z, making it an excellent choice for applications that demand high performance and low power consumption.

3. Efficiency and Performance of the MP2451DT-LF-Z

The MP2451DT-LF-Z achieves impressive efficiency through its synchronous rectification technique, which reduces the power loss typically associated with diodes in traditional buck converters. This technique, in combination with its fast-switching capability, ensures that the converter operates with minimal heat generation, even at higher output currents.

Its efficiency varies depending on factors such as input voltage, output voltage, and load current. However, it consistently provides efficiency ratings that are significantly higher than older linear voltage regulators or traditional buck converters. This efficiency is crucial not only for reducing energy consumption but also for minimizing heat generation and ensuring the stability of the overall system.

In practical applications, this high efficiency translates into several advantages, including lower power dissipation, reduced need for large heatsinks, and the ability to design more compact and lightweight power supplies. The result is an optimized system where the end user benefits from extended battery life, improved performance, and a longer operational lifespan of the power Management circuitry.

4. Application Areas of the MP2451DT-LF-Z

The MP2451DT-LF-Z is widely applicable in various sectors, thanks to its adaptability and efficiency. Some of the common application areas include:

Automotive: In automotive electronics, reliable and efficient power conversion is crucial for maintaining stable operations of sensors, infotainment systems, and lighting. The MP2451DT-LF-Z's wide input voltage range makes it suitable for use in automotive environments where voltage levels can fluctuate drastically.

Industrial Automation: Automation systems often require stable and precise power supplies to maintain the integrity of control systems, motors, and sensors. The MP2451DT-LF-Z helps power these systems with minimal energy loss, ensuring efficient operation even in industrial environments where power demands are high.

Consumer Electronics: Consumer electronics such as laptops, smartphones, and wearables rely on compact, efficient power management solutions to extend battery life and enhance performance. The MP2451DT-LF-Z provides an ideal solution, with its compact size and high efficiency supporting the performance needs of modern consumer devices.

Telecommunications: Telecommunications equipment, including routers, base stations, and other communication devices, also require efficient power conversion to ensure consistent and reliable operation. The MP2451DT-LF-Z can handle these demands with ease, offering a stable output voltage while minimizing energy waste.

Thermal Design and Heat Management for the MP2451DT-LF-Z in DC-DC Converters

As with any power electronics device, effective thermal management is essential for ensuring the longevity and reliability of the MP2451DT-LF-Z. While its high efficiency minimizes heat generation compared to older linear regulators, proper thermal design is still required, especially in high-power applications or environments with limited airflow.

1. The Importance of Thermal Management in Power Converters

Power converters such as the MP2451DT-LF-Z generate heat due to switching losses, conduction losses, and other internal factors. When heat is not efficiently dissipated, the temperature inside the converter rises, which can lead to thermal stress and eventual failure of components. Effective thermal management is, therefore, a critical aspect of the converter's design and performance.

A key factor to consider when designing a system around the MP2451DT-LF-Z is the power dissipation that occurs within the device itself. This is directly related to the efficiency of the converter: the lower the efficiency, the higher the power loss and, consequently, the greater the heat generated. By ensuring that the MP2451DT-LF-Z operates within its optimal thermal range, designers can extend the life of the device and improve the overall reliability of the system.

2. Key Thermal Design Considerations

To manage heat effectively in DC-DC converter designs, several strategies can be employed:

PCB Layout: Proper PCB layout is one of the most effective ways to manage heat dissipation. The placement of the MP2451DT-LF-Z on the PCB, as well as the routing of power traces, should be optimized to facilitate heat dissipation. Using wide copper planes for high-current paths and ensuring that there is adequate thermal via coverage for heat transfer are crucial for improving thermal performance.

Thermal vias and Copper Planes: Thermal vias are an important part of the thermal management system in power electronics. They allow heat to be transferred from the converter to other layers of the PCB, which helps to spread the heat across a larger surface area. Copper planes also play an important role by distributing heat more efficiently across the board.

Heatsinks and Thermal Pads: In some applications, especially those with higher power requirements or limited airflow, attaching a heatsink to the MP2451DT-LF-Z can be beneficial. A heatsink helps to increase the surface area for heat dissipation, allowing heat to be transferred away from the device more effectively. Thermal pads or thermal interface materials (TIMs) can also be used to enhance heat transfer between the MP2451DT-LF-Z and any external cooling elements.

Airflow Management: In systems where the MP2451DT-LF-Z is operating at higher currents or within enclosures, maintaining proper airflow is vital. Passive or active cooling methods, such as fans or forced-air systems, can help keep the temperature within the operating limits of the converter.

3. Measuring and Monitoring Thermal Performance

It’s essential to monitor the temperature of the MP2451DT-LF-Z during operation to ensure that it stays within safe limits. Thermal sensors and temperature monitoring ICs can be integrated into the design to track the temperature of the converter in real time. If the device gets too hot, the system can be designed to throttle down power output or shut down to prevent thermal runaway and damage.

4. Best Practices for Thermal Design

When designing a system using the MP2451DT-LF-Z, it’s essential to follow best practices for thermal design, such as:

Ensuring that the ambient temperature is within the recommended operating range.

Using high-quality components that are rated for high temperatures.

Testing the system in real-world conditions to verify that the thermal design is effective under load.

Considering the thermal impact of other components in the system that may contribute to the overall heat buildup.

Conclusion: Optimizing Performance and Longevity with the MP2451DT-LF-Z

The MP2451DT-LF-Z offers significant advantages in efficiency and versatility for DC-DC power conversion applications. However, to ensure the long-term reliability and optimal performance of the converter, effective thermal design and management are essential. By implementing thoughtful design strategies—such as optimizing PCB layouts, using thermal vias and heatsinks, and monitoring temperature—the performance of the MP2451DT-LF-Z can be maximized, ensuring that it continues to provide stable, efficient power conversion in a wide range of applications.

With its combination of high efficiency, low thermal impact, and adaptability to various power needs, the MP2451DT-LF-Z is a powerful solution for modern power systems that require reliable and efficient voltage regulation. By addressing thermal considerations from the start, designers can create more reliable and efficient products that meet the demands of today’s electronic and industrial applications.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.